Dralon Fabrics

Fabric Features:

- Soft;

- Warm;

- Moisture Management;

- Durable;

- Non-allergic.

Sampls available at request.

Dralon is the trademark of Dralon GMBH.

Dralon Fabrics

Fabric Features:

Sampls available at request.

Dralon is the trademark of Dralon GMBH.

Beta Textiles Co., Limited has launched a sportswear collection with fabrics containing graphene together with a graphene textile material partner in Shangdong Province, China.

As an innovative material with nano technology and derived from graphite, significantly improves performance for the benefits of athletes, professionals and sports enthusiasts. The major characteristics of this smart fabric is its ability to act as a filter between the body and the external environment, ensuring the ideal temperature of the wearer. The warmth produced by the human body is dispersed in warm climates, and preserved and distributed evenly in cold climates.

Further, graphene fabrics are electrostatic and bacteriostatic, sportswear made with such fabrics are able to reduce the friction with air and water to enable top sporting performance.

Functions of Graphene Fabrics:

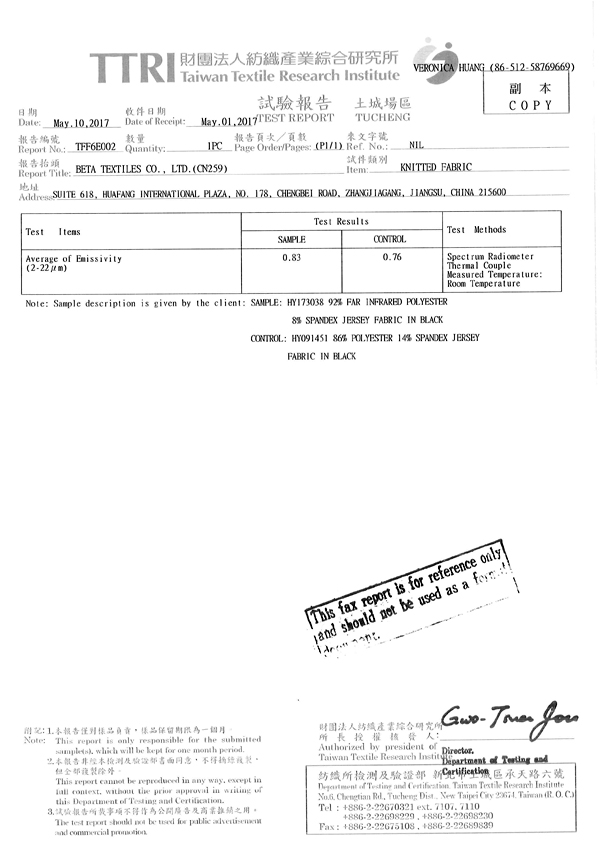

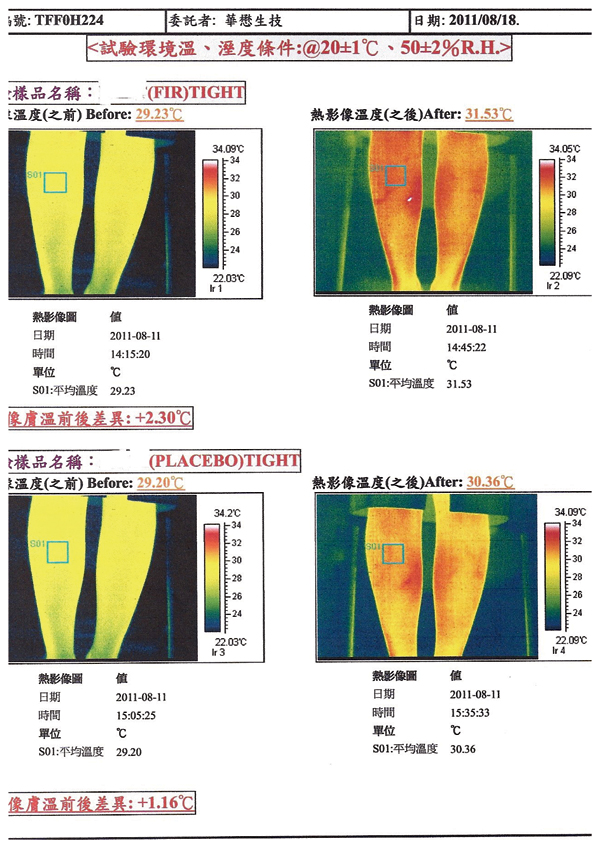

Far infrared radiation

Graphene fabrics release far infrared rays with a wavelength identical to water molecules in human cells. When such rays radiates on human bodies, resonance occurs with water molecules in human cells. Human surface cells will be activated, and microcirculation of human subcutaneous tissue will be accelerated to generate heat, improve health and immunity.

Graphene fabrics have great effects on improving human microcirculation. Compared with normal fabrics, blood flow rate improves by 141.34%, number of hemocytes increases by 61.73%, velocity increases by 50.07%, termperature increases by 4.21%, i.e. 1.27 °C.

Anti-microbial

Graphene fabrics are intrinsically anti-bacterial without any treatment.

Moisture Managment

Graphene fabrics provide excellent moisture management performance. It absorbs moisture and perspiration rapidly to keep the wearer dry and comfort.

Anti-static

Graphene fabrics provide excellent moisture management performance. It absorbs moisture and perspiration rapidly to keep the wearer dry and comfort.

Anti-UV

Graphene fabrics absorb UV to protect the wearer from UV radiations.

Green and ECO Material

BTEXCO uses a biomass graphene made with corn core cellulose as raw material. There is no chemical pollution in the whole process.

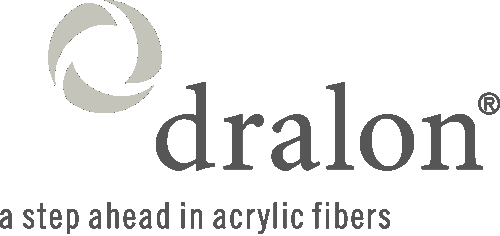

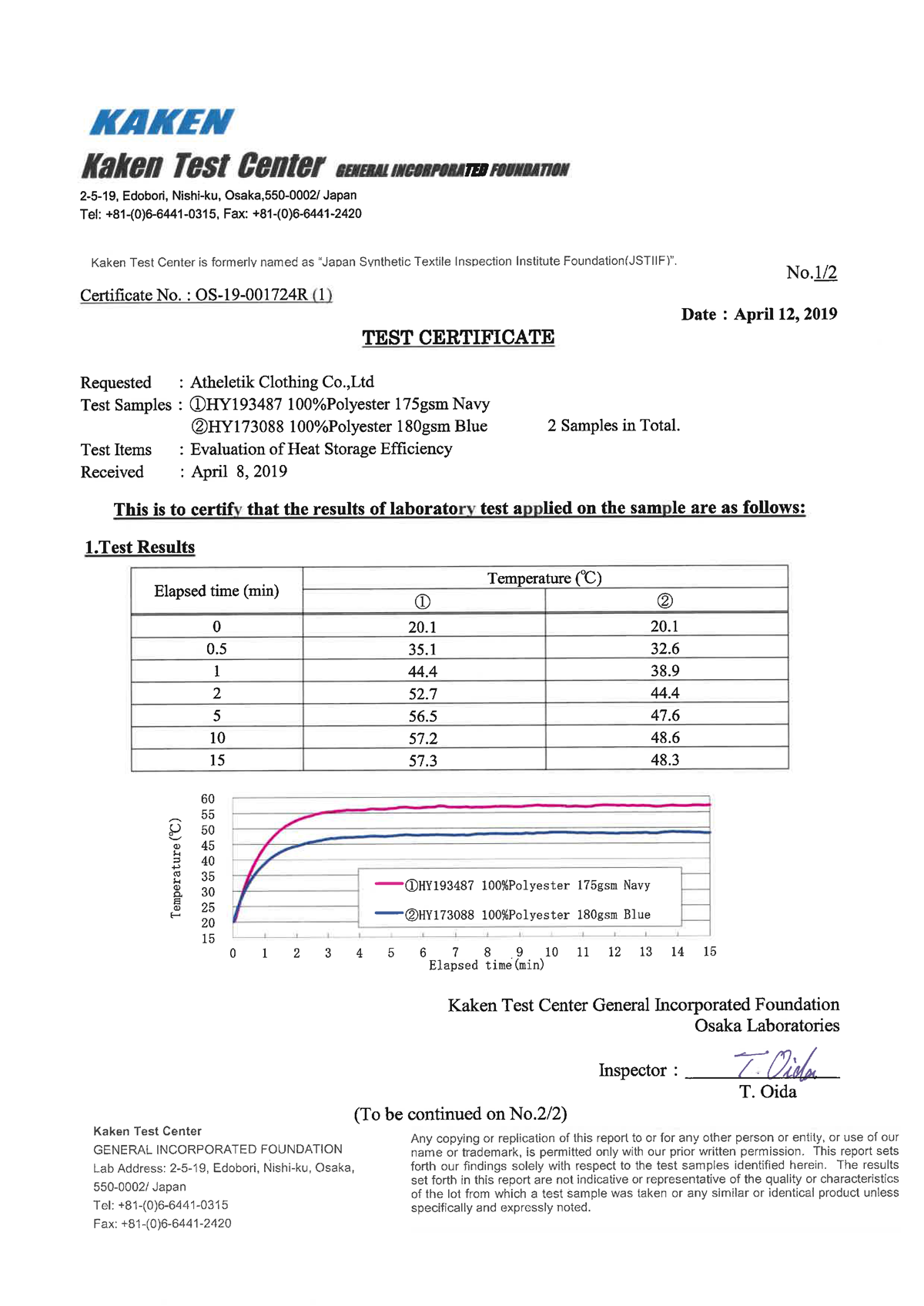

Heat Storage

Graphene fabrics absorb heat from the sun and human body, store it in the fabric to keep the wearer warm.

Based on tests with Kaken, the fabric temperature is 16 °C higher than fabrics made with normal polyester when the fabric is exposed to the sun.

Fabric ID: HY173038

Composition: 92% Far Infrared Polyester, 8% Spandex;

Weight: 240 g/m2

Width: 1.65m

Features of Far Infrared Fabric:

KWIKWARM Fabric Collection |

|||||

| Item# | Fabric ID# | Content | Weight | Technical Construction | Remarks |

| 1 | HY162888 | 51% Polyester 36% Polyester( Kwikwarm) 13% Spandex | 150 GSM | Jersey | striped, light weight |

| 2 | HY162924 | 46% Polyester 46% Polyester(Kwikwarm) 8% Spandex | 230 GSM | Jersey | striped, heavy weight |

| 3 | HY162951 | 95% Polyester 5% Spandex | 230 GSM | Fleece | Grid fleece |

| 4 | HY162995 | 60% Polyester 40% Polyester(Kwikwarm) | 150 GSM | Fleece | Blac/grey striped one side fleece |

| 5 | HY173050 | 47% Polyester 48% Polyester(Kwikwarm) 5% Spandex | 220 GSM | Fleece | Mini Grid fleece |

| 6 | HY173061 | 36% Polyester 54% Polyester(Kwikwarm) 10% Spandex | 180 GSM | Jersey | cationic poly/quickwarm jersey |

| 7 | HY173085 | 36% Polyester 54% Polyester( Kwikwarm) 10% Spandex | 180 GSM | Jersey | cationic poly/quickwarm jersey brushed |

| 8 | HY173096 | 100% Polyester (Kwikwarm) | 150 GSM | Interlock | Interlock brushed |

| 9 | HY173097 | 33% CD Polyester 67% Polyester (Kwikwarm) | 150 GSM | Interlock | intyerlock, non-brushed |

| 10 | HY173102 | 52% Polyester(Kwikwarm) 48% Polyester | 175 GSM | Fleece | polar fleece |

| 11 | HY173109 | 45% Polyester 55% Polyester( Kwikwarm) | 200 GSM | Mesh | piquet mesh |

| 12 | HY173204 | 45% Polyester (Kwikwarm) 45% Polyester 10% Spandex | 300 GSM | Fleece | Blac/grey striped one side fleece |

BTEXCO manufactures finished base layer garment with coconut shell charcoal fabrics.

Contact information:

Beta Textiles Co., Limited

Suite 618, Huafang International Plaza,

No.178, Chengbei Road, Zhangjiagang,

Jiangsu, China 215600

E-mail: info@betatextiles.com

1. Coconut Shell Charcoal Production

Coconut is a tropical plant whose shell is of no great use except for use as daily necessaries or art crafts. The production of coconut shell charcoal by utilization of the waste is a proactive eco concept.

Activated carbon will be created by heating the coconut shell fiber up to a temperature of 1200-1600 °C with the application of water vapor as activator. With an apparent size of more than 0.18mm (around 80 mesh), such particle-shaped activated carbon is also used in the purification of water and air.

2. Use of Coconut Shell Charcoal

Though the production of coconut shell activated carbon is costly, in addition to use in the purification of waste water from industrial activities and daily life, it is also used in the purification of tap water and other drinking water and also in the creation of purified water.

It is also recently being used in textile products,

3.Deodorization

Coconut shell charcoal absorbs odor through its surface. The surface area of 1 gram of coconut shell charcoal amounts to around 900-2000 m2 equivalent to the area of 4 basket ball courts. Such numerous micro pores will form a mechanism to absorb odor, stink and other toxic substance.

The finer the coconut charcoal particles are, the more pores the coconut shell charcoal will contain. The absorption of odor by coconut shell charcoal will not be reduced after grinding. This is why fine particles of coconut shell charcoal (normally submicron particles) provides extremely strong odor absorption.

4.Release of Anion

Both graphite structure (SP2) and diamond structure (SP3) exist in coconut shell charcoal. When friction with air is activated, electrons will be released into air (oxygen molecule). The positive charge thus released will create anion when the positive charge is being grounded via the conductive graphite structure. Anion provides microbe inhibition by nature.

5. Odor decomposition

Odor molecules will not be decomposed until and unless anions are created. This is why odor cannot be decomposed with activated carbon only.

Anions, as highly active oxygen molecule, will interact easily with odor molecules to result in oxygenation (combustion) whereby odor molecules are decomposed.

Coconut shell charcoal polyester normally contain 650 anions per cm3.

7.Dodorization compared with bamboo charcoal

Activated coconut shell charcoal provides better deodorization since its surface area is much greater than bamboo charcoal.

As activated coconut shell charcoal is made of coconut shell waste, it is widely accepted in North America and Europe as an ECO product.

8.Release of Far Infrared Ray

Release of FIR results in the oscillatory motion of particular molecules stimulated by heat. Any structure has a resonant oscillation frequency, i.e. frequencies at which the response amplitude is a relative maximum.

The diamond structure in coconut shell charcoal will create oscillatory motions when stimulated by heat. As its resonant oscillation frequency is precisely within the range of FIR( with a wave length of more than 4 micrometer), coconut shell charcoal will create the same effect of FIR when heated. The FIR emissivity of coconut shell charcoal polyester is normally more than 0.9.

9.Advantages of coconut shell charcoal fabrics

With coconut shell charcoal particles inside the fiber, fabrics made of coconut shell charcoal polyester will maintain its activity even after its use in finished garment. The coconut shell charcoal in the fiber will form a micro porous and moisture conductive surface to provide moisture management, dry and deodorization functions.

Fabrics with space dyed yarns are trendy fabrics for 2014 and the future. BTEXCO has developed a serires of space dyed fabrics including one side fleece, polar fleece etc. Sample swatches are available for clients to choose from.

In cooperation with YL Knitting, Zhangjiagang Beta Manufacturing & Textiles Co.,Ltd. has developed a high end fabric consisting of Dupont Coolmax and X-static silver fiber. In the mean time, it also supplies garment made of such fabric in flatclok stitching. The sewing is being contracted by HQ Clothing Co.,Ltd. which is about 50 minutes away from its head office.

X-static is a silver ion fiber that is naturally anti-microbial and healthy. With the nature of wicking property of Coolmax yarn, such fabric is perfect for sportswear, active wear.

The fabric is a mesh or piquet knitted on circular knitting machine. With the use of flatlock stitching in sewing, the garments in such fabric are really high end products for famous brands around the global.

X-static is the registered trademark of Nobel Biomaterials. All products from us using their fibre shall be subject to their certification.

Beta Textiles Co.,Limited started the production of bamboo charcoal fabric since 2005. The most regular construction is nylon, bamboo charcoal yarn and spandex dual face fabric to be used for underwear and sportswear. With features such as wicking, antibacterial, UV protection, odour free and thermal insulation etc, such fabric is idea for high end and high performance sportswear.

Production Processes of Bamboo Charcoal Yarn

4 year old bamboo Carbonization

To grind into nano grade powder

To convert into bamboo carbon fibre

To make bamboo cotton or baboo yarn

Main Functions

Infrared Releasing

UV Protective

Wicking

Thermal Insulation

Odour Removing

Multi-purpose

Fabric No: HY091364

Description: cationic/poly heather color four way stretch

Fiber: 50/50 cationic polyester/normal polyester blended yarn and spandex.

Construction: single jersey.

Finishing: cationic dyed;

Weight: 180 g/m2.

Composition: 43% cationic polyester, 43% normal polyester, 14% spandex

Fabric No: HY122040

Description: cationic polyester/spandex tricot

Fiber: 40D/12F cationic polyester, 40D spandex

Composition: 80% cationic polyester, 20% spandex

Machine gauge: 36

Special Features of Cationic Fabrics:-